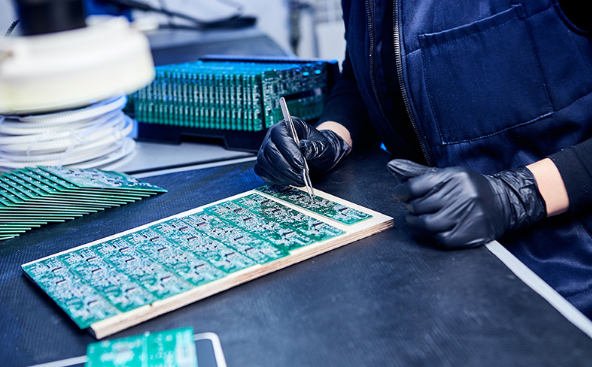

Printed Circuit Boards (PCBs) are at the heart of every electronic device, forming the framework that supports and connects various electronic components. For anyone involved in PCB fabrication in Singapore, selecting the right materials is not just a matter of preference but a fundamental decision that impacts performance, durability, and cost-efficiency. Understanding the criteria for material selection is vital, particularly in an industry where reliability and miniaturisation are key.

Understanding PCB Material Composition

A typical PCB consists of a substrate, copper layers, solder mask, and silkscreen. The substrate is the base material and serves as the insulating foundation, while copper layers form the conductive pathways. The solder mask prevents short circuits by insulating traces, and the silkscreen is used for labelling components.

Each of these layers must meet specific performance requirements based on the product’s intended use. High-frequency circuits, for instance, demand materials with low dielectric loss, while flexible PCBs used in wearable electronics require bendable substrates that maintain their integrity even under stress.

Key Factors When Choosing PCB Materials

One of the most critical decisions lies in selecting the substrate material. Common choices include FR-4, polyimide, and ceramic-based substrates. FR-4, made from woven fibreglass and epoxy resin, is the most widely used material due to its balance of cost and mechanical properties. However, for applications requiring higher heat resistance, polyimide may be a better fit.

When working with electronic manufacturing services in Singapore, engineers often begin by defining the product’s electrical and thermal demands. Will the PCB need to withstand high temperatures? Is the device designed for high-speed signal transmission? Will it operate in a high-vibration environment? The answers help determine the appropriate dielectric constant, thermal conductivity, and coefficient of thermal expansion.

Another important consideration is the number of layers in the PCB. Multi-layer boards, often seen in complex electronics like smartphones and medical devices, require materials that maintain signal integrity and mechanical stability across all layers. The selection of core materials and pre-preg (bonding sheets) becomes more nuanced in these cases.

Cost Versus Performance Balance

Material cost often plays a decisive role, especially in high-volume production. While high-grade materials offer better performance, they also come at a premium. In some cases, opting for advanced materials may be unnecessary, particularly if the device operates in a low-stress environment. Therefore, manufacturers must strike a balance between performance and budget.

In pcb printing in Singapore, this balance is commonly addressed during the prototyping phase. Multiple iterations allow engineers to test different materials under operational conditions, enabling data-driven decisions before moving into full-scale production.

For example, using copper of varying thicknesses can affect both performance and cost. Thicker copper enhances current carrying capacity but increases weight and production expenses. Hence, the choice must align with the application’s power requirements.

Environmental and Regulatory Considerations

Singapore’s focus on sustainable technology and eco-compliance means manufacturers also need to consider the environmental impact of materials used in PCBs. RoHS-compliant materials, which limit the use of hazardous substances, are now the industry standard. This includes lead-free soldering processes and halogen-free laminates.

Working with experienced providers of electronic manufacturing services in Singapore ensures that these requirements are met without compromising quality. Established service providers are well-versed in international certifications and local compliance standards, offering assurance in regulatory adherence.

Thermal reliability is another regulatory consideration, particularly for PCBs in industrial or automotive sectors. Materials with high Tg (glass transition temperature) and robust thermal cycling capabilities are critical for such demanding applications. Poor material choices can lead to delamination, warping, or even component failure over time.

Practical Tips for Material Selection

Design engineers should begin by thoroughly evaluating the end-use environment of the device. Will the board be exposed to moisture or extreme temperatures? Does it require mechanical flexibility? Once these questions are answered, narrowing down the material options becomes more straightforward.

It’s also beneficial to collaborate with specialists in PCB printing in Singapore during the design phase. These experts bring invaluable insights into the manufacturability and cost implications of various materials. Early consultation helps avoid costly design revisions and ensures that the selected materials are suitable for local production capabilities.

As the project nears the manufacturing stage, sample testing and quality assessments become crucial. Many suppliers offer sample runs to validate material performance before committing to large-scale orders. These trials can identify potential issues in signal transmission, thermal management, or mechanical resilience.

These considerations apply globally, and insights from PCB manufacturing in the United States show how advanced testing methods and strict compliance standards help ensure reliable production outcomes.

Conclusion

Selecting the right materials for PCB boards involves a delicate interplay between design needs, performance expectations, cost considerations, and environmental compliance. In Singapore’s competitive tech ecosystem, making informed material choices can greatly influence the success and longevity of your electronic products. Whether you are engaging in PCB fabrication in Singapore or partnering with providers for electronic manufacturing services in Singapore, taking the time to evaluate material options thoroughly is a worthwhile investment. For guidance and precision throughout your PCB journey, consult specialists in PCB printing in Singapore to ensure your boards are both efficient and future-ready.

Contact MPN Tech today to explore the best material options tailored to your design needs.