Large-scale operations generate a staggering volume of waste. From manufacturing plants to distribution centers, managing that waste efficiently is not just a matter of cleanliness—it’s a strategic necessity. In high-output environments, waste mishandling can drive up costs, increase safety hazards, and damage sustainability goals. That’s where industrial garbage compactors step in. These machines are more than just tools for crushing waste—they’re essential to modern waste management systems.

Managing Volume Without Compromise

In industrial settings, space is a premium resource. Waste materials can pile up quickly, eating into valuable floor space. Without an efficient system in place, businesses risk turning production zones into cluttered hazards. This isn’t just a visual or organizational problem—it directly affects workflow, safety, and even worker morale. By reducing waste volume at the source, compactors make space management easier and more reliable.

The Function And Value Of An Industrial Garbage Compactor

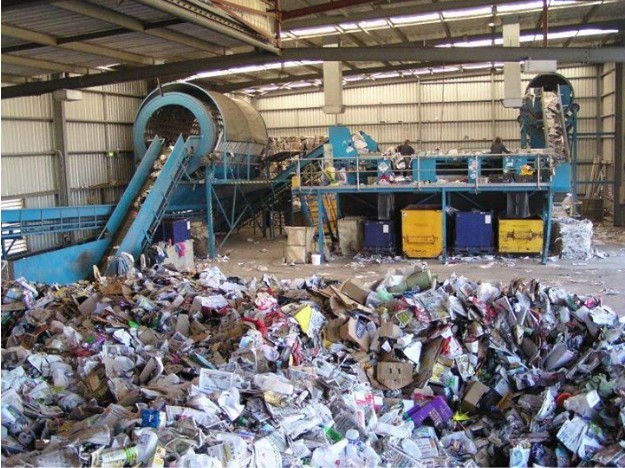

An industrial garbage compactor is a heavy-duty machine designed to compress high volumes of industrial waste into manageable units. Whether handling cardboard, plastic, metal scraps, or general debris, the compactor reduces the size and frequency of disposal trips. This translates into direct savings on hauling and landfill costs. It also reduces carbon emissions by requiring fewer transportation runs. In industries where margins are thin and sustainability matters, these benefits are significant when using an industrial garbage compactor.

Streamlining Daily Waste Handling With Industrial Garbage Compactors

Using an industrial garbage compactor eliminates the need for constant manual waste handling. Instead of multiple bins and repeated trips to dumpsters, waste is funneled into a single unit and compacted automatically or semi-automatically. This creates a cleaner, more organized facility. It also frees up workers’ time, allowing them to focus on productive tasks instead of wrestling with overflowing trash containers. Clean operations are efficient operations.

Reducing Environmental Impact With Smarter Waste Processing

Every compacted load of waste means fewer truckloads headed to landfills. That reduction isn’t just cost-saving—it’s environmentally responsible. Industrial garbage compactors help businesses meet regulatory compliance by reducing their overall waste footprint. Compaction also makes recycling easier. When materials are compacted and sorted properly, recycling centers can process them more efficiently, contributing to a cleaner supply chain.

Improving Workplace Safety And Sanitation

Loose waste is a known safety hazard. Slips, trips, and even fire risks increase when debris clutters walkways or workspaces. Industrial operations must prioritize safety as a daily standard, not an afterthought. Compactors contribute to a safer environment by keeping waste contained and controlled. They also help in maintaining better air quality and hygiene, especially in facilities dealing with food packaging or organic waste. A cleaner workspace promotes better health for all employees.

Boosting Operational Efficiency Across Departments

Waste might seem like a back-end concern, but it affects every part of a large-scale operation. Logistics, inventory, safety, and even HR departments benefit when waste is handled well. A reliable compaction system becomes part of the daily rhythm of operations. It ensures fewer interruptions, faster maintenance, and smoother communication between departments. It’s an investment in overall operational harmony, not just in garbage handling.

Conclusion

In the fast-paced world of large-scale operations, waste isn’t just something to discard—it’s a critical element to manage. The industrial garbage compactor plays a key role in transforming how businesses handle this challenge. By controlling volume, saving money, protecting the environment, and boosting safety, this powerful machine becomes a cornerstone of smart, sustainable growth.